Controlling Digital Outputs with Windmill Software

Push button control | Switching several digital outputs with one command | Automatically switching digital outputs depending on analogue input values | Using process mimics | Simple programming | Control via Active X

Windmill has several programs which you can use to control your digital outputs, including DigitalOut, AnalogOut, Graphics and Test-Seq. Additionally, the Windmill IML Tools make it easy for you control outputs from your own applications.

Windmill DigitalOut for Push Button Control

This software lets you control any number of digital output channels. It provides push buttons for you to change the state of each channel. You can switch each channel individually, or switch several channels at once.

Controlling Groups of Output Channels

You can group several digital channels together, so they are all switched on or off at the same time. You group them using SetupIML and then control them using AnalogOut.

Each digital channel (or line) is initially set to on or off by a single bit. When you want to always switch several channels at the same time - for example to open or close 8 relays at the same instant - you group up to 8 channels together. All 8 relays will now be controlled by a single value rather than by 8 separate ON/OFF values. In binary the value would be from 00000000 to 11111111.

Bit 0 corresponds to line 0, bit 1 to line 1, bit 2 to line 2 and so on. A value of 1 sets a line to on, a 0 sets it to off. So, for example, to set lines 0, 3, 6 and 7 to on and lines 1, 2, 4 and 5 to off you would send the following number in binary:

Data bits: 76543210 Binary: 11001001

In hexadecimal you would send "C9" and in decimal "201".

Automatically Switching Digital Outputs depending on Analogue Input Values

To do this you use the SetupIML software. Simply set alarm thresholds for each analogue input and link these to the digital output you want to switch. You can choose two thresholds for the each alarm, and select a different digital output to be triggered for each. This lets you, for example, automatically switch off a heater when a temperature rises above a certain point and then switch it back on if the temperature falls below another threshold.

Start SetupIML and double-click the analogue input channel which you want to monitor. Now select the Alarms button. You will be able to select your thresholds for switching the digital outputs.

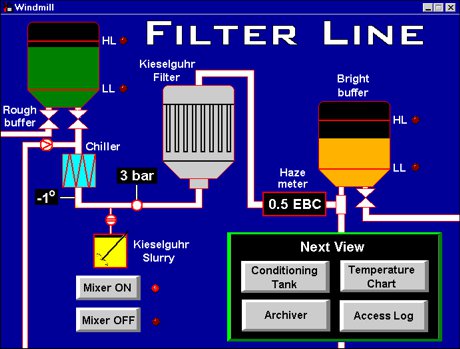

Windmill Graphics for Process Mimics

Graphics lets you design and create your own display

and control windows. You can insert buttons to control

digital outputs. These can take any appearance you

like. There are three types of button: one that

toggles between on and off, one that always turns an

output on and one that always turns an output off.

You can also insert "LEDs" to light up when the

output is on. Finally, you can choose whether the

the digital output should initially be on or off.

For more details see

https://www.windmill.co.uk/graphics.html

Windmill Test-Seq for Sequence Control of Equipment

Test-Seq interprets a file of commands and controls

equipment and applications accordingly. It can send

commands and data to other Windows programs, or directly

to the hardware inputs and outputs. The command, or

test sequence file is a text file which you can easily

create in a text editor or word processor. Use

Test-Seq to control digital outputs depending on

timing or environmental conditions. For more

details see

https://www.windmillsoft.com/daqshop/test-control.html

Windmill IML Tools - Control via Active X

You can use the IML Tools to switch digital outputs

directly from Windows applications like Excel, from

JavaScript code running on a web page, from Visual

Basic programs or from any developer tool can

integrate Active X controls. Windmill takes care of

the communication with the hardware leaving you

free to concentrate on your application. For more

details see

https://www.windmillsoft.com/daqshop/programming-tools.html

All the Windmill programs mentioned can be used with equipment connected to the PC over Ethernet, USB, RS232, RS422, RS485 or Modbus. Contact Windmill Software at sales@biodataltd.com for more information.