Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 194, September 2014

Welcome to Monitor. Don't forget that subscribers can download our free ComDebug data acquisition software. Should you wish to remove yourself from our mailing list, go to Monitor Newsletter

You can download Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor194.pdf

Any questions, comments or data acquisition stories, get in touch.

Contents

* How to choose an accurate, reliable and efficient measurement system

* Questions on using Windmill: Instrument, Device, Module and Channel

* DAQ News Round-up

How to choose an Accurate, Reliable and Efficient Measurement System

When choosing a measurement and control system, you'll consider the obvious features such as number and type of inputs and outputs, communications used, sampling speeds, and so on. However, less attention is often paid to features that make the system easier to use, more functional and that bring the overall cost down.

Analysis of Data

- Can the data be analysed and compared in real-time with the raw data? This is particularly useful in applications where raw data needs to be processed and then compared with some standard values in pass/fail applications.

- Can the saved data be automatically archived in a logical, easily accessible, way? This aids the procurement of historic data when accountability is needed, for example if failures occur after production.

- Is the data suitable for input into a Statistical Process Control procedure? Used in PID (proportional, integral, derivative) applications to control a process depending on the relationships with raw data values.

Automation

- Can the tests or experiments be automated - improving repeatability?

- Can the system not only log data unattended, but also detect and shut down if any problems are detected?

- Can reports be generated directly from the software? This often leads to more accurate data as it eliminates the risk of transcription or typographical errors.

Pitfalls

When considering all the requirements for your data acquisition system, which can often take much deliberating and last for many months, it is important not to get bogged down with unnecessary details. There are a few common pitfalls that you should be aware of.

- Having a large committee of people involved in the decision making process can blur the ultimate goal of the system. As a first step compose a list of requirements and priorities, and refer to this throughout the process.

- Not seeing the hardware and software as intrinsically linked, and assigning a separate hardware and software specialist that have little or no contact with one another. A demand in one area is generally linked to the other. It may also produce difficulties if any problems arise, as the technical support will need to know how the hardware and software behave together.

- Trying to choose hardware and software without a clear understanding in your own mind of exactly what is required is also a problem. Telling the manufacturer exactly what you have at the moment, what you will need from the system, and any long-term future requirements will make the whole process much easier. Trying to work it out as you go along and moving the goal posts half way through, will almost certainly lead to failure.

- Choosing a manufacturer that doesn't offer comprehensive technical support is another obvious pitfall. If you need to change your set-up, or if someone else takes over the project, adequate technical support can be invaluable. The same is true of course if any failures occur with the system.

- Finally don't eliminate equipment that doesn't contain every single feature that everyone working on the project needs at the moment, or would like to have in the future. Manufacturers can never design a system that will please everybody, all the time. So unless you want a complete custom solution, which is potentially very costly, trying to find some middle ground is usually the best way to avoid shutting out solutions that are otherwise well suited to the application.

I hope these points have given you a better idea of how to progress if you are currently considering a computerised measurement system, or indeed if you wish to upgrade a system you already have. The aim is to obtain a system that doesn't just put data on a screen for you, but gives a complete solution to make your process more accurate, reliable and efficient.

By Ben Worthy

Questions on Using Windmill: What do Instrument, Device, Channel and Module mean?

Question

Can you tell me conceptually what is meant by:

1) Instrument

2) Device

3) Channel

4) Module

Answer

Instrument and Device

An instrument and a device are conceptually the same. Your system might have one or many devices. For example, if you had a gps providing position readings and an echo sounder providing depth readings you would have two devices.

Channel

During data acquisition different parameters are collected, for example humidity, wind speed, strain, resistance and temperature. Each parameter is said to be collected through a "channel". So you might have one channel holding temperature readings and another holding pressure readings. If, say, you were measuring temperatures at four different points on a cooker, you would have four channels of temperature data.

Module

Some data acquisition devices are designed to be able to provide many different types of data. For example, a Microlink 3000 comprises a frame into which you could slot a counting module, a strain measurement module and a temperature measurement module. Each of these modules offers several "channels". So the Microlink 3000 is a device holding, amongst others, a temperature module which is wired to several different temperature sensors or channels.

Microlink 3000 holding several modules

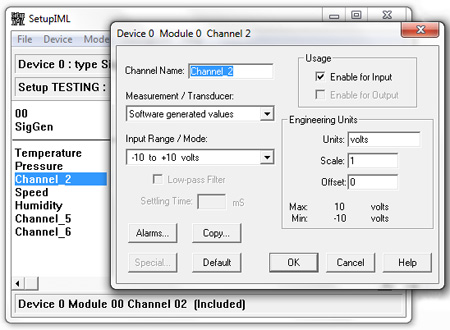

Device > Module > Channel

With the Microlink example, in the Windmill SetupIML software you would see one device containing several modules and under each module you would see several channels. If, though, you had just an electronic balance connected, you would see one device (the balance), one module (which is not physically there but it keeps things consistent throughout the software) and one channel delivering the weight measurement.

SetupIML software: Configuring Channel_2 which is in

Module 00 in Device 0. (Numbering starts from Zero.)

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition or Google+ - https://plus.google.com/107072683025496630222/

Google Glass could speed assembly time at General Motors

General Motors is test driving Google Glass as part of its research into how wearable information technology could help productivity in its sprawling car factories.

Source: Wall Street Journal

http://blogs.wsj.com/

Robotic hand to feel its way to deep-sea discoveries

A three-fingered hand with a keen sense of touch could probe the murky depths when other sensors fail, helping to fix problems at deep-sea oil and gas wells.

Source: New Scientist

http://www.newscientist.com/

Industrial wireless installations to surge

BCC Research predicts the global wireless sensor devices market to grow at almost 24%, with industrial use greater at over 34%.

Source: BCC Research

http://www.bccresearch.com/

Tire Sensor for Industrial Trucks Solves a Burning Problem

A research project of the Hannover University is currently developing a sensor system that enables operators to monitor the conditions of tires for industrial material handling vehicles.

Source: EE Times

http://www.eetimes.com/

Study Finds Alarming Lack of IoT Security

How secure is the Internet of Things (IoT)? Not very, according to a new report from Hewlett-Packard Co. After evaluating 10 of the most popular IoT-enabled devices—mostly consumer products such as TVs, webcams, home thermostats, remote power outlets, sprinkler controllers, door locks, home alarms, garage door openers—HP's security research organization found that most contain potentially serious security vulnerabilities.

Source: Manufacturing Leadership

http://www.gilcommunity.com/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

FREE DATA ACQUISITION SOFTWARE

As a thank you for subscribing we offer you the

ComDebug data logging and Com port trouble-shooting

software for free. Log data over RS232, RS422, RS485

or Modbus. Also included is a free month's trial of the

Windmill 7 logging, charting and control programs.

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/

Google+

Subscribe to Monitor

Comments

Tip: For a speedy response, when using Google+ comments alert us by adding +Windmill Software