Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 219,November 2016

Welcome to Monitor, the data acquisition and control newsletter.

You can also download Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor219.pdf.

Contents

* Your Questions Answered: How to Collect Data from Sensors in the Sea

* Excel Corner

* Data Acquisition News Round-up

Your Questions Answered: How to Collect Data from Sensors in the Sea

Weblink: https://www.windmillsoft.com/daqshop/rs232-modbus.html

Question

Dear Sirs,

We are interested in Windmill 7 Data Acquisition Software + COMIML Serial Driver. We have two environmental buoys with salinity sensors. The sensor must receive a control to measure (Ctrl+Q Ctrl+Q pvalue,). The system must send the command every 2 minutes (possible we will need to modify this interval).

The received data from the sensor is a string (Ctrl+Q Ctrl+Q pval, TT.TTT, CC.CCC, SS.SSS).

The data must be saved in a database for show them through website (this step can be done by ourselves). Could the Windmill 7 cover our requirements of sending the command, receive the string and store it in a file or database?

Answer

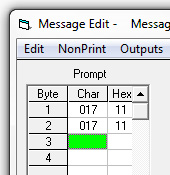

Yes. During set-up sse the ComDebug program to enter the control commands. You will need to enter them as either decimal or hexadecimal values. Using our Control Code Conversion table we see that Ctrl Q is decimal value 017 and means Xon or "transmit on". Click Send to check that the sensor sends back data, and then Parse to extract the readings from the data string.

You could either use ComDebug's timing settings to specify an instrument idle time of two minutes (used with Read in Background) or use the Windmill Logger program to specify a data logging time of two minutes.

Once you've verified the communications work, Logger will continually record readings and store them in a file.

Control code conversion table is at https://www.windmill.co.uk/ascii-control-codes.html

Excel Corner: Adding the Units to all Cells in a Column

Web link: https://www.windmill.co.uk/excel/

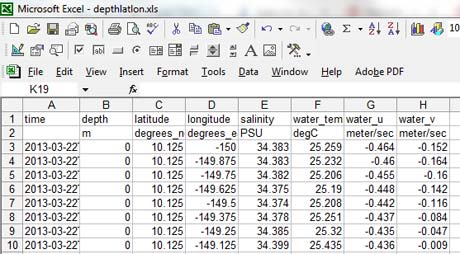

Windmill Logger saves data in text format so you can import the file into Excel. It saves the data in a series of columns, each column holding one channel's values.

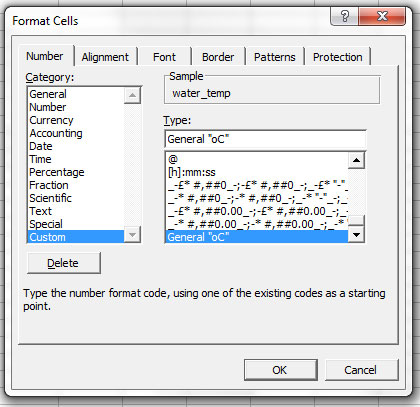

The units of the readings are shown at the top of the column. You could format the cells though, to show the units alongside the readings. Or, indeed, to add any text you liked. To do this

- Select a column of data to format.

- Right-click and choose Format Cells.

- Choose Custom.

- Type into the box General "units", where units might be oC or m/s, and click OK.

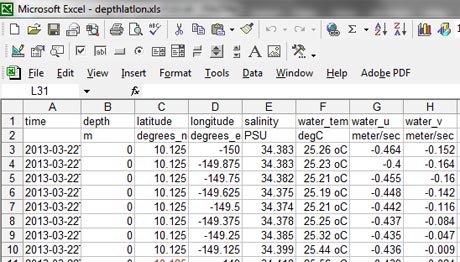

All the readings will have their units appended within the cell, as shown in column F below.

You can still perform operations on these value - adding them together for example. The result will also have the units appended, even though you haven't specifically configured the results cell to do this.

More tips on using Excel are at https://www.windmill.co.uk/excel/excel-tips.html.

If you have a question about using spreadsheets for data acquisition and analysis - email monitor@windmillsoft.com.

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition - or grab our rss feed.

Mussel-strong glue bonds underwater sensors

Engineers are using a protein produced by mussels to create a reversible synthetic glue that not only can bond securely underwater - but also may be turned on and off with electricity.

Source: SCUBA News

http://news.scubatravel.co.uk/

Shaking Things Up With More Control

A new algorithm can help machines avoid damage or malfunctions from resonant frequencies. This month, Samsung recalled 2.8 million washing machines due to excessive vibrations that could cause the top to break off. The vibrations happen when the normal oscillations of the washing machine become trapped in resonance, causing it to shake harder and harder at the resonant frequency.

Source: American Institute of Physics

http://news.wisc.edu/

New Improved Piezoelectric Sensor Technology Holds Promise

Piezoelectric sensors measure changes in pressure, acceleration, temperature, strain or force and are used in a vast array of devices. However, these sensors often can be limited by the "white noise" they detect that can give false readings. The improved sensors amplify the signal, allowing the same amount of sensors to read more data. They also cut costs by allowing fewer sensors to cover larger structures and longer distances.

Source: University of Missouri

http://munews.missouri.edu/

Engineers create Radiation Sensor for Space

University researchers have created an ion sensor that can detect higher radiation in space. The sensors will be placed on weather satellites and launched into space from Florida.

Source: University of New Hampshire

https://www.unh.edu/

Novel Sensing Technologies Present Growth Opportunities across Industries

The sensors and instrumentation technologies need to: achieve a high signal-to-noise ratio; minimise false positives and negatives; consume less power; enhance accuracy of sensed data; and be fit for operation across a wide temperature range in order to fulfill their growth opportunities. That's according to a new report from Frost and Sullivan.

Source: Frost and Sullivan

http://ww2.frost.com/news/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

DOWNLOAD DATA ACQUISITION SOFTWARE

As a thank you for subscribing we offer you the ComDebug data logging and Com port trouble-shooting software. Log data over RS232, RS422, RS485 or Modbus. Also included is a month's trial of the Windmill 7 logging, charting and control programs.

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/