Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 2521, September 2019

Welcome to Monitor - thank you for subscribing. Any comments or questions email monitor@windmillsoft.com. For a full archive of back issues see windmill.co.uk/newsletter.html

Contents

* Multiple Measurements: Multiplexing or Simultaneous Sampling?

* Your DAQ Questions Answered: Measuring Thermocouple and Voltage Signals

* Data Acquisition News Round-Up

Multiple Measurements: Multiplexing or Simultaneous Sampling?

Web link: https://www.windmill.co.uk/multiplexing.html

When data acquisition equipment receives an analogue signal, it digitises it - converting it to number that the computer can understand. This is done by an analogue-to-digital converter. However, what happens when monitoring multiple signals? Clearly, one A-D converter cannot digitise all the signals at once. There are two answers to this: provide an A-D converter for each analogue input, or switch (multiplex) the signals in turn to one A-D converter.

Do you need Simultaneous Sampling?

In true simultaneous sampling the data acquisition hardware provides an A-D converter for each analogue input signal. Providing sampling is initiated from a single clock source, this both permits simultaneous sampling and ensures that there is no reduction in sampling rate as the number of inputs increases. However, this method is very expensive.

Multiplexing - a more Economical Option

The second, and more common, approach is to use a single analogue-to-digital converter and switch each signal in turn to the converter. This is a much cheaper solution. However it does not provide simultaneous sampling across the inputs and as more inputs are added the maximum sampling rate is reduced per input. For example, if your system can read 1 input channel 100 times a second, when reading 10 input channels it is limited to 10 readings per second per channel. Our Microlink 75x and 85x data acquisition units use multiplexing.

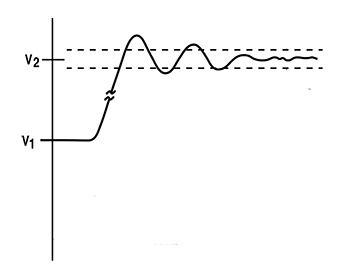

Settling Time and Cross Talk: Reducing Inaccuracies

As the multiplexer switches one input after another to the A-D converter, you must allow time for each reading to settle to its new value. This settling time defines the minimum interval between reading each input: the inter-channel interval. If you try to go faster than this there will be increasing cross-talk between channels, leading to inaccurate results.

Mixing Small and Large Signals

Low-level signals, like thermocouple voltages, take longer than higher voltages to settle to their true value. It's always good practice to group inputs according to their the signal sizes. Some data acquisition systems let you set different inter-channel intervals for different groups of channels. This is especially valuable when streaming data directly to disk at high speeds. For slower applications, software like Windmill lets you set different settling times for different channels.

Another consideration when monitoring different sized signals, is being able to choose the range of each input channel individually. The range refers to the maximum and minimum voltage that will be digitised by the A-D converter. It's always best to choose the smallest range that encompasses the signal, as this optimises resolution. For low speed applications (Hz) some software will automatically select the best range for you, but this should be turned off for high speed applications (kHz). Independent ranges lets you mix, say, thermocouples, 2 V instrumentation outputs and 4-20 mA process signals in one multiplexed scan.

Burst Scanning: Quick Read of all Channels followed by a Delay

When collecting data fairly slowly it is possible for the scan rate (the total time to read all the channels once) to be much slower than the minimum inter-channel interval suggests. In this case it may make sense to sample the channels fairly quickly once a scan starts, giving readings that are taken closer together in time and so more easily compared, then have a break between scans. This known as burst scanning.

Mixing Fast and Slow Changing Signals: Split-Rate Scanning

Suppose you are monitoring an engine. You are recording pressure signals from the cylinders as well as coolant temperatures. It is sensible to record the pressure signal much more often than the coolant temperature. This leads to the idea of split-rate scanning where a subset of channels is recorded every scan, while all channels are recorded every nth scan.

Channel Sub-Sets: Changing Test Runs

For test applications, you may be monitoring some inputs in one test run and a completely different set of inputs in another. The ability to select a sub-set to scan is important to avoid having to rewire your connections each time you want to record some other data.

Data Acquisition Software for Multiplexed Inputs

Windmill software supports low-speed multiplexed systems with independent input ranges and channel sub-sets. Streamer software supports higher-speed multiplexed systems with independent input ranges, channel sub-sets, inter-channel intervals, burst scanning and split-rate scanning.

The data acquisition systems sold by Windmill Software all use Multiplexing. See https://www.windmillsoft.com/Your Data Acquisition Questions Answered: Measuring Thermocouple and Voltage Signals

Web link: https://www.windmillsoft.com/daqshop/thermocouple-measurement.html

Question

The Microlink 751TC can accept 16 input channels all at once and log them as time-series data using the Windmill software that comes with the Microlink, correct? So, in my case I'll have three TC's and one 0-10V signal and the Windmill software will be logging all of those at the same time. Does the Windmill software output the TC signal as temperature? Or does it only return the micro volt signal? I see there's a known relationship between millivolts and temperature depending on the thermocouple type and it would be great if I could just input the thermocouple type and have it output the temperature.

Answer

Yes, you just select the type of thermocouple in Windmill SetupIML and Windmill will show and save the data as a temperature in your choice of units.

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition - or grab our rss feed.

New Guidelines for Optimising HMI Usability and Performance Published by ISA

Human-machine interfaces (HMIs), the primary means by which users interact with industrial processes, provide the potential and opportunity to greatly enhance operations - or to confuse users and degrade operations.

Source: ISA

https://www.isa.org/

Scurrying Roaches Help Researchers Steady Staggering Robots

Human-machine interfaces (HMIs), the primary means by which users interact with industrial processes, provide the potential and opportunity to greatly enhance operations - or to confuse users and degrade operations.

Source: Georgia Tech

https://www.news.gatech.edu/

Using Smart Sensor Technology in Building Design

Researchers find apprehension of using technology may stifle architectural innovation

Source: San Diego State University

https://business.sdsu.edu/

Sensor system could expose Pollutors

Novel sensor system could soon help safety agencies establish wrongdoing: placed in a sewage canal, it detects relevant substances and helps isolate and expose polluters.

Source: Franhofer

https://www.fraunhofer.de/

Tunabot mimics speed and movement of Yellowfin Tuna

Tunabot study helps better understand the physics of fish propulsion that could eventually inform development of the next generation of underwater vehicles, driven by fish-like systems better than propellers.

Source: SCUBA News

https://news.scubatravel.co.uk/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/