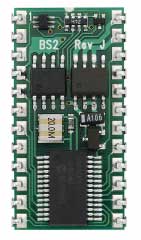

Turn your Parallax Basic Stamp into a multi-channel datalogging instrument

Windmill software lets you continually log data from Parallax BASIC Stamps, and other instruments with an RS232 serial port, on a PC running Windows. All data is time-stamped and can be imported into Excel either during or after data collection. Alternatively, subscribers to the Monitor newsletter (ISSN 1472-0221) can download free logging software: ComDebug. This lets you log data from one instrument and save it in a text file. After collection is finished data can be imported into Excel.

- Run the Windmill ConfIML program and enter your Stamp's communication settings.

- Run the Windmill SetupIML program and choose names and units for your Stamp's data.

- Run the Windmill DDE Panel, Logger or Chart program to save or display data from your Stamp.

After you have entered your configuration settings with ConfIML and SetupIML, you don't need to use these again and can go straight to the logging and display programs. More details on entering the configuration settings are below. If you wish you can transfer data in real-time to other programs like Excel.

The BASIC Stamp is already noted for the ease it has brought to resolving control technology problems. Its use of the BASIC language with inbuilt control instructions can dramatically shorten industrial development time. The Windmill software can read ASCII data and can be configured to pass it directly to an application such as Excel. The BS2-IC debug statement is additionally useful here because it makes it easy to format ASCII data in a manner that's both applicable to both Windmill's and Excel's requirements. Exploiting the situation to the full turns the BS2-IC into a Windmill multi-channel datalogging instrument. For details how a Parallax BASCI Stamp and Windmill have been used in a teaching environment, see our application story.

Run the Windmill ConfIML program

This detects and saves a record of the hardware you want to use. You need to add the LabIML ASCII instrument handler and enter your Stamps's communication settings. To do this

- Press the Add button.

- Select LabIML RS232 ASCII Instrument Handler.

- Type a name for the Stamp, a description and enter how many channels of data you will be collecting. The name and description can be anything you like. Each channel holds one type of data item: for example temperature measurements. Press OK.

- Enter your instrument's settings. If your Stamp program regularly sends data, these settings should work:

- Reading Protocol: Continuous

- Data Persistence: 10000

- Instrument Idle or Wait Time: 0

- Returned Message Length: Count how many characters are in the Stamp's message - this depends on your Stamp's program.

- Instrument Initialisation String: Leave blank.

- You now need to define how to extract data. To do this press the Channels button. What you enter here depends on your Stamp program. Let's assume that the BS2-IC produces an output of ASCII strings that range from "-55.0" to "+120.0" with a leading sign character, a trailing carriage return to mark the end of data and a maximum length of seven characters. In this case to extract the data you could ignore characters until meeting a "+" or "-", then extract everything until the carriage return. This looks like:

\I"+-"\E"\C013"

- The next step is to enter your communications settings.

Baud rate: 9600

Data bits: 8

Parity: none

Flow control: none.

- Save your settings and close ConfIML.

Now Run the Windmill SetupIML program

Here you can name your channel, set its units, any alarms and so on.

- From the Device menu select LabIML.

- Your data channel will be shown as a number like 10000. Double click this channel.

- Type name for your channel and make sure Enable for Input is checked. If you want to change the units enter an appropriate scale and offset.

- Save your settings in a *.ims file and close SetupIML.

Open Windmill DDE Panel

- From the File menu select Load Hardware Setup and choose the *.ims file you just saved.

- Connect your Stamp channel. You should see the correct data in DDE Panel.

- Proceed similarly for the Logger and Chart programs.

Getting the data into Excel

You can use the Windmill Logger program to collect data, and after collection has finished import it into Excel. Alternatively, you can collect data with Excel in real-time by using an Excel macro to read data from the Windmill DDE Panel. For more details see our Excel page.

Success?

Have you successfully used Windmill with your Stamp? Let us know about your project.

If you have any problems fill in the form on our technical support page.

Related Topics

RS232 Driver Software

Technical Support

RS232 Standard and Trouble-Shooting Com Port Problems

Serial Driver

Com Port Settings

Example Serial Instrument Settings