Saving the environment by using eggshells instead of cement

Web link: https://www.windmill.co.uk/parse.html

Every day, millions of waste eggshells are thrown away by poultry farms, householders, bakeries and the food industry around the world.

But they can be recycled as a cement replacement in concrete, according to new research published in December's Structures Journal.

The cement industry is the third largest industrial energy consumer and the second largest CO2 emitter. So not only would using egg shells reduce waste, it would also cut down on climate-change factors CO2 and fossils fuels.

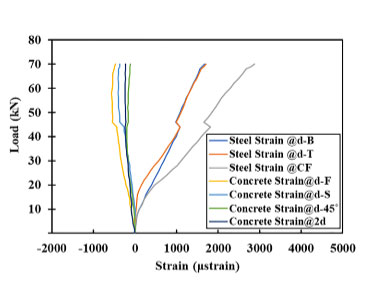

Lead by Lavan J.Mahmood, the researchers compared the strength of different concrete mixes made with various levels of cement and eggs shells.

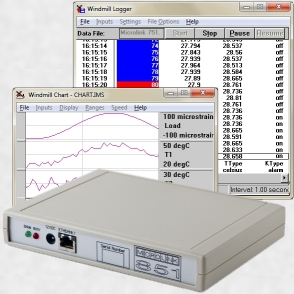

They bonded four strain gauges onto each slab of concrete to measure compression strain in two directions. They also connected a LVDT. To automatically capture the data from the strain gauges and LVDT, the engineers used a Microlink 851 data acquisition unit and configured it with Windmill software. Windmill also controlled outputs, logged data and sent it to an Excel spreadsheet via Windows Notepad.

The Microlink 851 conects to the computer over Ethernet. As well as strain, it enables measurement of voltage, temperature, pressure, pH and current..

The researchers found that shear strength and stiffness increased by 5.85% and 24% respectively for concrete made with 10% egg shell powder.

Further Reading

Mahmood L J et al, Punching shear behavior of reinforced concrete flat slab column connection containing recycled eggshell powder, Structures, Vol 46, 2022, Pages 1016-1028, https://doi.org/10.1016/j.istruc.2022.10.133.

Microlink 851 with Windmill software works over Ethernet or Internet.