Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 192, July 2014

Welcome to Monitor. I hope you find it useful - if you wish to download our free data acquisition software please subscribe to do so. Should you wish to remove yourself from our mailing list, go to Monitor Newsletter

You can download Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor192.pdf

Any questions, comments or data acquisition stories, get in touch via email, Twitter or Google+.

Contents

* Using Counters and Timers

* Questions on Using Windmill: Which Strain Measurement Package?

* Excel Corner: Saving the Data Every Hour

* DAQ News Round-up

Using Counters and Timers

Counters are often used in data acquisition. Digital pulses can be counted, frequency measured and the time between pulses or the width of pulses recorded.

For simple counting applications the main concern is that counts shouldn't be missed. When software reads the counter regularly for long periods, it is sensible to reset the counter to zero each time. You should also consider whether the count will exceed the capacity of the counter. A 16-bit counter will count up to 65535. Cascadable counters allow a carry count to be used to join two counters together: two 16-bit counters become one 32-bit counter. What happens is that when a counter reaches its maximum count it produces a voltage pulse. You can use this as an input to another counter, thus continuing the count.

It is often useful to have an output latch facility. This is storage in hardware for the count. On a command from software, the contents of all counters are simultaneously transferred to their output latches. This means that you can take a snapshot of the counters without disturbing the on-going count, especially important with cascaded counters.

Frequency measurement works by counting pulses over a defined gate time, typically between 0.1 and 10 seconds. The gate time should be long enough to count sufficient pulses to give a good resolution of the frequency. The longer the gate time, though, the less often the frequency can be updated. For example, if the pulse rate is 100 Hz (cycles per second), then a gate of 0.1 seconds will count 10 pulses giving a resolution of only 10%, while a gate time of 1 second will count 100 pulses. Some hardware, like the Microlink 840 we sell, will also record the maximum, minimum and average frequency. Frequency measurement is useful when measuring speed or the rate of power consumption.

The Microlink 840 for data logging and counting

A period timer measures the time taken for a number of cycles of the input signal to occur. At the end of each measurement the counter resets to zero. You can use this, for instance, to measure the speed of a conveyor belt by timing the interval between consecutive pulses.

Some hardware will also measure the time that a signal is true, or the time between a start and stop pulse. You could use this to record the time when a machine is running. The timer will record how long the On signal is true and software calculates the percentage of time the machine is in use simply by comparing the total count with elapsed time.

More Information

For more on your counting or timing application, please contact Windmill Software - sales@biodataltd.com. All the data acquisition units we sell provide counters in addition to their other functions - more information is at https://www.windmillsoft.com/

Questions on Using Windmill: Which Strain Measurement Package?

Question: Measuring Strain

I found 851-SG (875 GB pounds) and 751-SG (575 GB pounds) on your web page. I would very much appreciate it if you kindly tell me the difference between 851-SG and 751-SG.

Answer

Both these systems let you monitor 16 strain gauges, switch digital outputs, count events and have the option to also measure temperature, pressure and current. They differ in two ways. Firstly you can use the 851-SG as stand-alone data logger, whilst the 751-SG has to be continuously connected to a PC. Secondly you read data from the 851-SG over Ethernet or the Internet whereas you connect the 751-SG to the computer using USB.

More on the 851-SG and the 751-SG is at https://www.windmillsoft.com/, or contact sales@biodataltd.com.

Excel Corner: Saving the Data every Hour

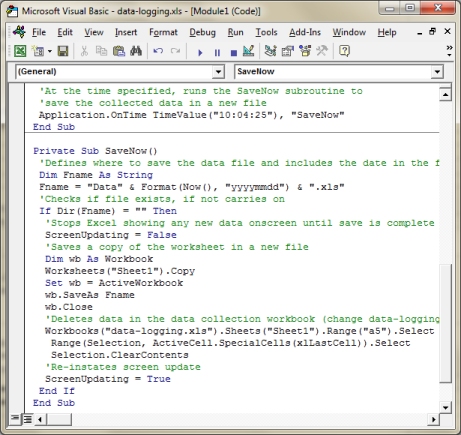

When using Windmill to log data to Excel, you can automatically save the data at regular intervals. We discussed how to save once a day in issue 179 (archived at https://www.windmill.co.uk/monitor179.html). You can use the same code, with a minor modification, to save data more frequently.

How to Save Data Every Hour

If you look at the example spreadsheet given in Issue 179 (which you can download from https://www.windmill.co.uk/excel/data-logging.xls) you will see code to run the SaveNow routine at the specified time each day:

Application.OnTime TimeValue("18:18:25"), "SaveNow"

To change this to save every hour use:

NextSaveTime = Now + TimeValue("00:01:00") Application.OnTime NextSaveTime, "SaveNow"

You also have to edit the filename in the SaveNow section. Originally the date was appended to each file. For saving hourly we want the time to also be added to the filename. Change

Fname = "Data" & Format(Now(), "yyyymmdd") & ".xls"

to

Fname = "Data" & Format(Now(), "yyyymmddhhmm") & ".xls"

Don't forget that if you don't need live data in Excel, you can use Windmill Logger to regularly save data to different files and then open the data file in Excel later for processing. No need for any macro programming to collect the data.

Further Reading

Windmill Logger

Excel Tips and Tricks for Data Acquisition and Control

If you have a question about using Excel for data logging please get in touch.

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition or Google+ - https://plus.google.com/107072683025496630222/

Swimming, climbing robots explore the hostile Arctic

The biggest experiment of its kind is camped out on the ocean north of Alaska. The machines could revolutionise our understanding of Arctic sea ice.

Source: New Scientist

http://www.newscientist.com/

Embedded sensors aim to curtail fatigue-related accidents

Injuries and fatalities caused by fatigue-related accidents could be curtailed

with sensors embedded into seatbelts.

Source: The Engineer

https://www.theengineer.co.uk/

A battery-less sensor chip for the internet of things

A prototype sensor saves power by using transistors that never fully turn "on".

Source: MIT Technology Review

http://www.technologyreview.com/

Waste paper turned into a super-spongy battery

Treat paper in the right way and it can become a form of porous carbon capable

of sucking up charge - making it the perfect battery for storing wind energy

Source: New Scientist

http://www.newscientist.com/

Sensor measures degree and occurrence of goose bumps

A team of researchers at KAIST in Daejeon, South Korea, has developed a flexible,

wearable 20 x 20 mm polymer sensor that can directly measure the degree and

occurrence of goose bumps (technically known as piloerection) on the skin -

caused by sudden changes in body temperature or emotional states.

Source: Electronics Online

http://www.electroline.com.au

Global sensor market to grow by 10%

The global market for sensors and related technologies is expected to grow to

nearly $154.4 billion by 2020, with a five-year compound annual growth rate of

10.1%, according to a report by BCC Research.

Source: BCC Research

http://www.bccresearch.com/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

FREE DATA ACQUISITION SOFTWARE

As a thank you for subscribing we offer you the

ComDebug data logging and Com port trouble-shooting

software for free. Log data over RS232, RS422, RS485

or Modbus. Also included is a free month's trial of the

Windmill 7 logging, charting and control programs.

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/

Google+

Subscribe to Monitor

Comments

Tip: For a speedy response, when using Google+ comments alert us by adding +Windmill Software