Monitor - ISSN 1472-0221

The Newsletter for PC-Based Data Acquisition and Control

Issue 224, April 2017

Welcome to Monitor, the data acquisition and control newsletter. Thanks for subscribing.

You can download this issue of Monitor as a pdf file from https://www.windmill.co.uk/monitor/monitor224.pdf.

Contents

* Microlink 770 helps Compression Testing Research

* Your Data Acquisition Questions Answered

* Excel Corner: How to Highlight the Maximum Value in Each Row

* Data Acquisition News Round-up

Compression Testing Researcher Uses Microlink 770

Weblink: https://www.windmill.co.uk/materials-compression-testing.html

Ilias Stavrakas, Assistant Professor of the Laboratory of Electronic Devices and Materials in Greece, has been investigating compression tests of Dionysos marble.

He repeatedly subjected the marble to increasing loads. To measure the stress on the marble he used Kyowa strain gauges attached to a Microlink 770 with a 120 ohm resistor bridge, and ran Windmill Streamer software to record the strain readings.

The Microlink 770 is a high speed data acquisition unit which connects to the computer over USB. It is a versatile unit which, with appropriate hardware, can measure not only strain but temperature, pressure, voltage or current through 16 analogue input channels.

Windmill's Streamer software saves readings to disk and can capture pre- and post-trigger data. It measured the bridge excitation and automatically adjusted the strain results to compensate for any changes in excitation.

The initial unstrained bridge measurement was much larger than the change in measurement due to strain. Streamer balanced (zeroed) the bridge giving a precise reading.

Streamer can save data in a variety of formats. These include ASCII for loading into software like Excel, and binary for compact file storage.

The Kaiser Effect

Repetitive loadings of brittle materials like marble cause internal damages that gradually expand, leading to inevitable failures. Interestingly, a structure will only suffer further internal damage if exposed to stresses higher than previously encountered. This is known as the Kaiser effect. First investigated by Joseph Kaiser in 1950, when a material experiences a new, higher load, it emits acoustic waves - but only after the initial load or stress level is exceeded.

However, all is not that straightforward - there is the problem of the Felicity ratio. This is when the Kaiser effect doesn't apply as expected.

The Microlink 770 and Streamer software helped Professor Stavrakas discover that the Felicity ratio strongly depends on the stress range to which the material is subjected, with regard to the deformation region.

Further Reading

Microlink 770: High Speed Data Acquisition

STAVRAKAS, Ilias. Acoustic emissions and pressure stimulated currents experimental techniques used to verify Kaiser effect during compression tests of Dionysos marble. Fracture and Structural Integrity, [S.l.], n. 40, p. Pages 32-40, apr. 2017. ISSN 19718993. Date accessed: 20 Apr. 2017. doi:http://dx.doi.org/10.3221/IGF-ESIS.40.03.

8 Tips for Computerised Strain Measurement

Your Data Acquisition Questions Answered: How to Enable Logger Buttons?

Weblink: https://www.windmill.co.uk/logger.html

Hi

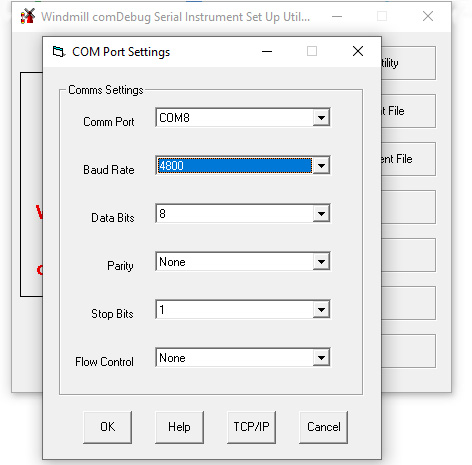

Having problems running the Logger. Have installed a parser for RS232 NMEA which works under ComDebug's Run mode. But on starting the Logger all the buttons are disabled. When opening the file menu for loading the hardware setup - Windmill requests files *.ims which I don't have.

ComDebug receiving NMEA data from a Geolux Flowmeter over RS232.

Answer

Run the SetupIML program. This will create a default *.ims file holding the details about your NMEA devices. Save this then go to Logger and choose Load Hardware Setup from the File menu. Logger's buttons will then be enabled.

If you wish, in SetupIML, you can customise the default *.ims file. For example, you can set levels which if crossed would cause an alarm, or change engineering units.

For more information on Logger and the other Windmill programs see https://www.windmillsoft.com/.

Excel Corner: How to Highlight the Maximum Value in each Row

Using Excel's conditional formatting abilities you can highlight the maximum value in each row of your data.

- Select the first row of data.

- From Excel's Home or Format menu choose Conditional Formatting.

- Choose to use a formula for the condition.

- Into the Formula box type

=B10=MAX($B10:$F10)

where the first row of data is row 10, the first data value (as opposed to the date or time) is in column B and the last data value of the row in column F.

Note the absolute and relative references. The first B10 is a relative reference - when copied across cells it refers to the new cell position. The $B10 means the column reference will always be column B. - Choose how you want to highlight the maximum value - changing colours of text and cell for example. Close the Conditional Formatting box.

- Copy row 10.

- Select the rest of the data table.

- From the Edit menu choose Paste Special and then Formats.

- The maximum value in each row is now highlighted.

For more Excel tips see https://www.windmill.co.uk/excel/

DAQ News Round-up

Welcome to our round-up of the data acquisition and control news. If you would like to receive more timely DAQ news updates then follow us on Twitter - @DataAcquisition - or grab our rss feed.

New material for cheap, fast, portable sensors

Chemists have developed a material that holds the key to cheap, fast and portable new sensors for a wide range of chemicals that right now cost government and industries large sums to detect.

Source: University of Texas

https://news.utexas.edu/

Ethical industry means more long-term prosperity

An ethical approach to industrial strategy isn't just a 'nice to have', it is a key factor in long-term economic prosperity says Dr Stuart Parkinson, executive director, Scientists for Global Responsibility

Source: The Engineer

https://www.theengineer.co.uk/

IoT UK Boost Award goes to Retail Sensing

Smart City technology developed by Retail Sensing has enabled them to win an IOT UK Boost award from The Science and Technology Facilities Council (STFC).

Source: Retail Sensing

http://retailsensing.com/

Graphene "fish scale" coating will warn of structural damage

A material made of overlapping layers of graphene (atom-thick sheets of carbon) changes colour according to the level of stress applied. This could be used in structures to provide early warning of damage.

Source: SCUBA News

http://news.scubatravel.co.uk/

* Copyright Windmill Software Ltd

* Reprinting permitted with this notice included

* For more articles see https://www.windmill.co.uk/

We are happy for you to copy and distribute this

newsletter, and use extracts from it on your own web

site or other publication, providing the above notice

is included and a link back to our website is in place.

For previous issues by subject see https://www.windmill.co.uk/monitorindex.html

DOWNLOAD DATA ACQUISITION SOFTWARE

As a thank you for subscribing we offer you the ComDebug data logging and Com port trouble-shooting software. Log data over RS232, RS422, RS485 or Modbus. Also included is a month's trial of the Windmill 7 logging, charting and control programs.

SUBSCRIBING OR CANCELLING SUBSCRIPTION Visit https://www.windmill.co.uk/newsletter.html and add or remove your e-mail address.

Windmill Software Ltd, PO Box 58, North District Office,

Manchester, M8 8QR, UK

Telephone: +44 (0)161 834 6688

Facsimile: +44 (0)161 833 2190

E-mail: monitor@windmillsoft.com

https://www.windmill.co.uk/

https://www.windmillsoft.com/